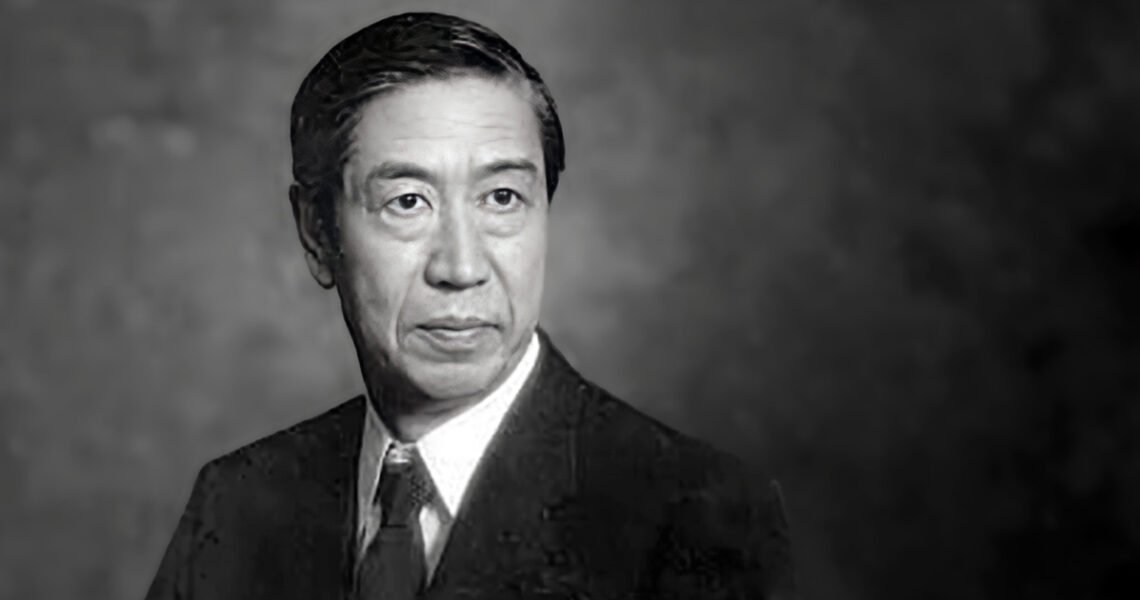

Know Your Lean Guru: Genichi Taguchi’s Quiet Revolution in Quality Thinking

Every once in a generation, someone steps into an industry and quietly rewrites the rules. Genichi Taguchi did exactly that. He was not a loud reformer, nor did he chase spotlight or status. Yet the ripple of his ideas still shapes how companies design products, develop systems and think about variation. In many ways, the modern emphasis on building quality into the earliest stages of design traces straight back to him.

Taguchi’s life began far away from the factories and laboratories where he would later leave his mark. Born in Tokamachi, a textile town known for its kimono heritage, he grew up surrounded by craftsmanship and precision. His first ambition was to join the family business. But the turbulence of the 1940s pushed him in another direction when he was assigned to the Astronomical Department of the Imperial Japanese Navy. This unexpected detour exposed him to measurement, data and the discipline of scientific thinking.

When the war ended, Japan was rebuilding almost everything—from infrastructure to industry. Taguchi found himself working at the Ministry of Public Health and Welfare, where he met one of the most important influences of his life, statistician Matosaburo Masuyama. Their conversations opened Taguchi’s eyes to the potential of designing experiments rather than relying on trial and error. His later work at the Institute of Statistical Mathematics and his involvement in improving penicillin production gave him practical experience in applying statistical ideas to real problems.

Everything accelerated in the early 1950s when he joined the Electrical Communications Laboratory of Nippon Telegraph and Telephone. Japan at that time was hungry for industrial revival, and Taguchi found himself in an environment where every improvement mattered. Influenced by the teachings of W. Edwards Deming and surrounded by engineers trying to match Western innovation, Taguchi began refining the ideas that would later carry his name across the world. It was here that he realised something simple but profound: real quality is created long before a product reaches the assembly line.

His international collaborations strengthened these ideas even further. During his fellowship at the Indian Statistical Institute, he worked closely with C. R. Rao and learned about orthogonal arrays, a concept that allowed engineers to run sophisticated experiments without drowning in complexity. His later interactions with John Tukey at Princeton and the eventual acceptance of his methods at Bell Labs turned what was once considered unconventional into a global practice. Companies like Ford, Xerox, Boeing and ITT became strong adopters once they discovered the cost savings and performance improvements Taguchi’s system could deliver.

His Contributions That Changed the World of Industrial Quality

Taguchi’s work often appears technical when explained formally, but the heart of it is surprisingly intuitive. A few of his major ideas include:

The Taguchi Loss Function

Instead of thinking that a product is fine as long as it sits “within tolerance,” Taguchi argued that any movement away from the ideal target creates a loss to society. Quality is not a pass-or-fail event; it has a cost curve.

Off-line Quality Control

He pushed industries to focus on the design stage rather than relying on inspection at the factory floor. When a product is designed correctly, everything downstream becomes smoother.

Innovations in the Design of Experiments

His use of orthogonal arrays made experimentation faster, efficient and accessible to engineers who were not statisticians. He also introduced the idea of using an outer array to represent uncontrollable real-world factors, allowing engineers to test robustness before the product ever existed.

These ideas helped organisations reduce variation, simplify decision-making and build products that performed consistently despite unpredictable environments.

Recognitions and Honours Across the World

Taguchi never worked for fame, yet recognition followed him throughout his career. His honours paint a clear picture of his global influence:

• Deming Prize for Individuals (1960)

• Willard F. Rockwell Medal of the International Technology Institute (1986)

• Indigo Ribbon from the Emperor of Japan (1989)

• Recognised as a “Quality Guru” by the British Department of Trade and Industry (1990)

• Honorary member of the Japanese Society of Quality Control (1995)

• Honorary Fellow of the Institute of Directors, India (1996)

• Automotive Hall of Fame Inductee (1997)

• Honorary member of the American Society for Quality and the American Society of Mechanical Engineers (1998)

• Honorary President of the Robust Quality Engineering Society of Japan (1999)

Each honour represents a different industry, yet all of them point toward one truth: Taguchi’s thinking broke through borders and languages because it solved universal problems.

Books That Carried His Ideas Into New Generations

Taguchi wrote and co-authored several influential works that helped thousands of engineers and quality leaders understand his methods more deeply. A few of his well-known titles include:

Introduction to Quality Engineering (1986)

Taguchi on Robust Technology Development (1992)

Robust Engineering (1999)

The Mahalanobis-Taguchi System (2000)

The Mahalanobis-Taguchi Strategy (2002)

Computer-Based Robust Engineering (2004)

Taguchi’s Quality Engineering Handbook (2005)

These books did not just teach techniques. They encouraged a mindset—one that challenges noise, variation and inconsistency by approaching design with calm, structured thinking.

A Legacy That Still Shapes How We Build and Improve

Genichi Taguchi’s influence continues to live inside every modern quality system, even when people using those systems may never have heard his name. His legacy is not simply statistical tables or formulas. It is an idea:

Quality is created with intention, not by chance.

And that single belief has helped industries save billions, improve reliability, protect consumers and shape the philosophy that Lean practitioners apply every day.

Taguchi remains one of the most important pioneers of quality engineering, a quiet mind who changed how the world thinks about designing for excellence.