Thailand’s Quiet Revolution in PCB Manufacturing

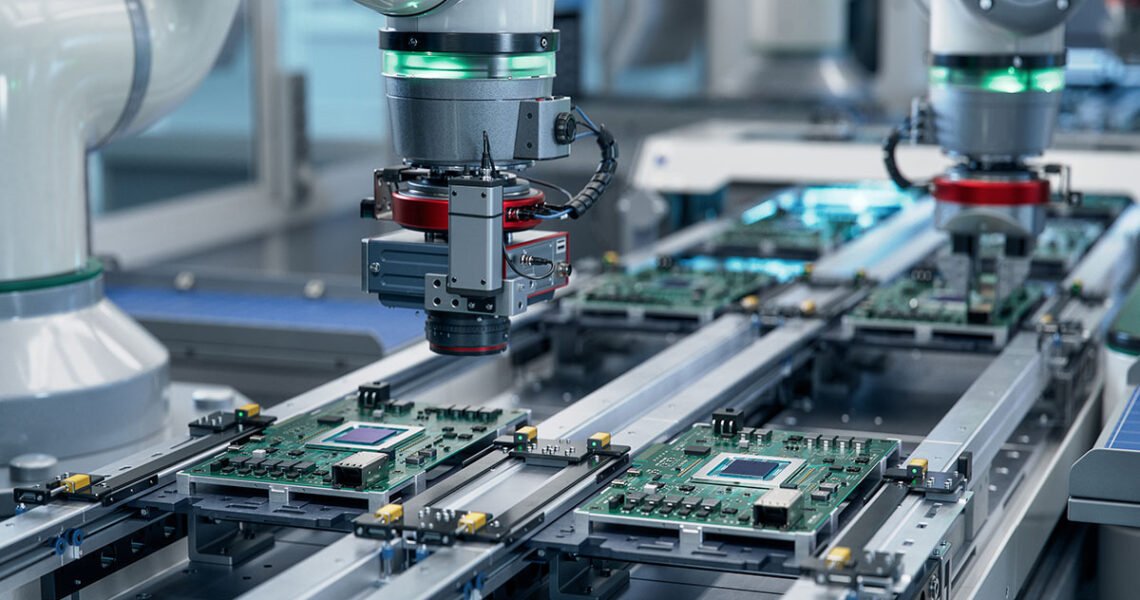

In a world electrified by the promise of artificial intelligence, a quiet transformation is unfolding in Southeast Asia. While headlines often focus on chip design and semiconductor breakthroughs, another part of the supply chain is taking center stage. Thailand is emerging as a critical hub for printed circuit board (PCB) manufacturing, an industry that forms the backbone of every device powering the AI era.

From AI Demand to PCB Expansion

PCBs may not carry the same glamour as chips, but they are indispensable. They serve as the foundation where chips, capacitors, resistors, and connectors are mounted. Without PCBs, smartphones, electric vehicles, AI servers, and supercomputers could not function. As global demand for AI hardware surges, so does the need for more advanced PCBs.

Thailand has become a magnet for PCB investment. Victory Giant Technology, a major Chinese PCB manufacturer and a key supplier for Nvidia, has already expanded operations in Ayutthaya. Taiwan’s Gold Circuit Electronics, another supplier linked to Nvidia’s networking equipment, is running full production at its Thai facility. Global leaders such as Zhen Ding Tech and Unimicron are also setting up shop in the country.

This shift is not coincidental. It reflects the “Taiwan plus one” strategy, where manufacturers diversify outside Taiwan to reduce geopolitical and supply chain risks. Following heightened US China tensions and concerns about security around Taiwan, Southeast Asia has emerged as a safer alternative. In less than three years, nearly 60 PCB manufacturers from China and Taiwan have established operations in Thailand.

Government Support and Policy Push

The Thai government is not standing on the sidelines. Through the Thailand Board of Investment (BOI) and agencies such as the Ministry of Higher Education, Science, Research, and Innovation, the government has been rolling out policies to attract high tech investors. From 2022 to mid 2025, Thailand approved more than 500 electronics investment projects valued at about 19.5 billion US dollars. Around 180 of those projects are in the PCB sector, contributing roughly 200 billion Thai baht to the economy.

The government has also launched Thailand Electronics Circuit Asia (THECA), a dedicated exhibition platform designed to highlight the country’s role as a PCB hub. It brings together global manufacturers, suppliers, and investors under one roof. At THECA 2025, Thailand declared its ambition to capture 10 percent of global PCB exports and cement its position as the leading hub in ASEAN.

Beyond attracting factories, Thailand is tackling a crucial challenge: skilled manpower. Industry experts predict that the PCB sector will need an additional 80,000 trained workers by 2027. To meet this demand, the Thailand Electronics Circuit Center has been established to provide workforce development, training, and certification. The government has also pledged to train 280,000 people across semiconductors, electric vehicles, and AI over the next five years. This includes tax incentives, scholarships, and collaboration between universities and industry.

The Strategic Location Advantage

Thailand’s position in ASEAN is also a strength. It offers connectivity to neighboring manufacturing powerhouses such as Vietnam, Malaysia, and Singapore. Many PCB components produced in Thailand are integrated into assembly lines in these countries before being exported worldwide. This creates a regional ecosystem that makes Thailand more resilient to external shocks.

At the same time, the government is promoting industrial estates and science parks, such as Thailand Science Park and the National Electronics and Computer Technology Center. These hubs foster research, collaboration, and technology transfer between companies and academic institutions. They provide the infrastructure needed to support advanced PCB and semiconductor-related industries.

Lean Thinking as a Competitive Edge

Despite its advantages, Thailand faces challenges. Rising labor costs, infrastructure gaps, and fluctuating global demand could slow progress. This is where Lean manufacturing becomes a game changer.

Lean is not simply a set of tools to reduce waste. It is a philosophy that empowers people, streamlines processes, and creates a culture of continuous improvement. In the PCB industry, where precision and efficiency determine profitability, Lean can deliver significant impact.

Key benefits of Lean in PCB manufacturing include:

- Waste Elimination: Identifying and removing bottlenecks, reducing rework, and minimizing excess inventory.

- Cycle Time Reduction: Speeding up production lines without sacrificing quality, critical for AI-driven demand.

- Defect Prevention: Using Lean quality control methods to reduce errors and improve yield.

- Workforce Empowerment: Training employees to solve problems directly on the shop floor, boosting engagement and productivity.

- Scalability: Applying standard Lean practices across multiple factories to maintain consistency as the industry grows.

Lean is particularly relevant for Thailand’s PCB sector because many companies are starting with small production lines. With Lean, these firms can expand more smoothly, reaching economies of scale while keeping costs under control.

True North Lean’s Role in Southeast Asia

One consulting firm well positioned to support this transformation is True North Lean. As one of the prominent Lean consulting firms in South and Southeast Asia, True North Lean has built a reputation for guiding companies through cultural and operational change. Unlike firms that provide one-off training, True North Lean embeds its consultants into organizations, working alongside management and shop floor teams to build sustainable systems.

In the context of Thailand’s PCB industry, True North Lean can help companies:

- Build standardized production systems to ensure high quality across multiple sites.

- Train workers and managers to think critically about process improvement.

- Develop continuous improvement programs that align with corporate strategies.

- Create leadership alignment around a “True North” vision, ensuring that every improvement effort supports long-term goals.

For new entrants to Thailand, particularly companies relocating from China or Taiwan, Lean consulting also provides a soft landing. It enables them to integrate into Thailand’s ecosystem more effectively, aligning local workforce practices with global standards.

A Human Story of Transformation

Consider a PCB factory in Ayutthaya. Rows of machines hum as workers assemble boards for AI servers. Overhead, AI-powered inspection systems flag potential defects, reducing waste by 30 percent. Production supervisors gather daily in short meetings, using Lean tools to track progress and solve issues in real time. Employees on the line suggest layout improvements that reduce material travel and speed up output.

This is not a futuristic vision but a practical reality when Lean practices are adopted. The benefits are felt not only in higher profitability but also in greater pride among the workforce. For Thailand, a country investing heavily in its people, Lean provides a framework to unlock human potential.

Looking Ahead

By 2030, Thailand aims to become the second-largest PCB hub in the world, just behind China. To achieve this, it must continue attracting investment, building talent pipelines, and embedding operational excellence. Global companies are betting on Thailand because of its stability, location, and policy support. Lean consulting can ensure that this wave of investment turns into long-term competitive advantage rather than short-term gains.

The AI era is still in its early stages. Demand for PCBs will only rise as supercomputers, data centers, and electric vehicles multiply. If Thailand maintains its current trajectory and embraces Lean as part of its industrial DNA, it could become one of the three pillars of the global technology supply chain alongside China and Taiwan. This would mark not only an economic success but also a story of resilience and strategic foresight.

References

- Nation Thailand, “Thailand emerges as a top hub for PCB production as nearly 60 companies set up factories,” 2025.

- Thailand Electronics Circuit Asia (THECA) 2025 Report.

- Bangkok Post, “NBTC pledges to support Thailand’s PCB industry,” 2025.

- Reuters, “Thailand targets 280,000 workforce in high-tech sectors over 5 years,” 2024.

- Reuters, “US firms keen to diversify supply chains, supercharge Thai investments,” 2024.

- Thailand Board of Investment (BOI) Investment Data, 2022–2025.

- True North Lean, “Our Team and Consulting Approach in Asia,” 2025.